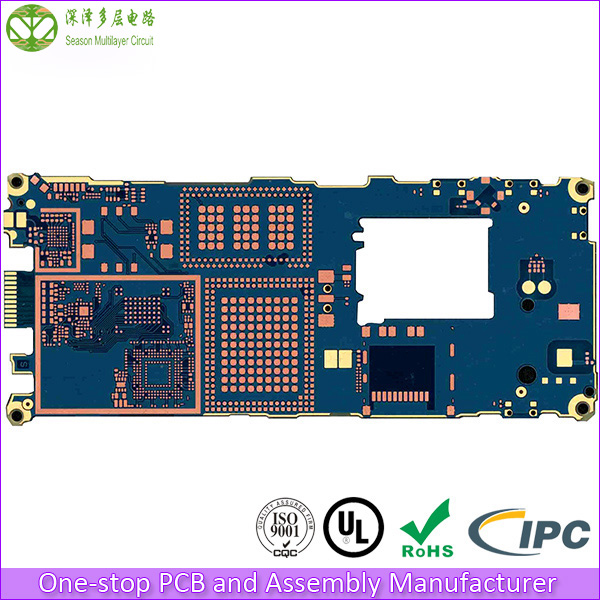

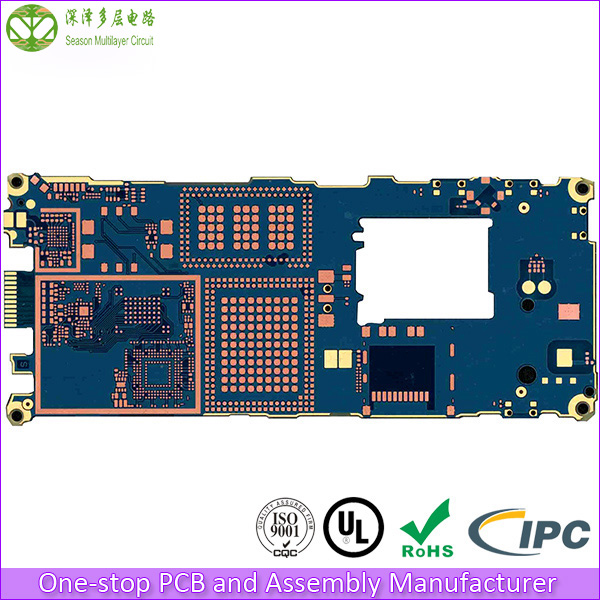

image: PCB prototype 4 layer with Blue Solder Mask

Quick turn HDI PCB Prototype

We specialize in rapid PCB services with an industry leading turnaround time supporting 24 hours, 48 hours and 72 hours for 2layer, 4layer, 6layer and 8layer printed circuit boards. When in demand of fast and rapid PCB prototype boards, you can count on Heros Electronics to deliver high quality printed circuit boards on time at competitive prices.

PCB prototypes

With extensive prototype PCB fabrication capabilities, advanced equipment and skilled workers, we are confident that we will be able to exceed your simple or complex PCB prototype requirements.

Reliable HDI PCB prototyping services with the highest quality

For PCB prototyping, we are able to manufacture low volume single and double-sided PCBs to complex multilayer PCBs with blind and buried vias at affordable prices. From an electronic hobbyist to an established fortune 500 company, we are able to handle all of your rigid PCB prototyping requirements in-house Shenzhen.

Low volume HDI PCB prototypes

We provide the most cost efficient solution for PCB prototyping to our customers. Without MOQ, you will get the enough PCB prototype boards with the minimum cost. Also, Heros Electronics doesn't put any restrictions for prototype boards. We are committed to straight forward pricing that you can rely on every time.

Do you need rapid HDI PCB prototyping with quick turnaround times?

Quick turnaround PCB For the past years, engineers, assemblers, and designers from around the world have counted on us for their quick turn PCBs. Companies big and small know that they can depend on us for their mission-critical PCBs. We have an industry leading on-time percentage that customers have come to love. We understand the importance of delivering on our promises, so we have a rock solid customer satisfaction guarantee. If you are ever unhappy with your order, we are quick to make sure that we make it right. Unlike PCB brokers, we manufacture our boards in-house, so our entire printed circuit board manufacturing process is more agile. We can answer your questions directly, without having to relay information to another PCB house. If you need to know what materials we have in inventory, your current order status, or make any urgent changes, you know that you are dealing directly with the manufacturer and that you have accurate and timely information.

Lead time is critical when prototyping a new PCB design. It is a competitive advantage for your business to test out your designs at a faster rate than your competitors. Today, larger companies like HUAWEI, BYD, TLC, LENOVO are purchasing faster lead times to get to market faster. Let us know more about your products and goals, so we better understand what you need from us to be more successful.

Get a Fast HDI PCB Prototypes Quote with Heros Electronics

You can directly send us your information via email. We are confident that once you have experienced the Heros Electronics's difference, you will continue to use us for all of your future quickturn PCB business. We look forward to quoting your PCBs and earning your business.

Specialized in one-stop PCB and Assembly manufacturing, Heros Electronics is committed to providing quick-turn high quality PCB and PCBA to our customers all over the world with affordable price. Every circuit board is fabricated as per strictest standards in compliance to IPC class II, IPC class III, UL, RoHS and others, which ensures the PCB board and product assembly is done to exceed the requirement of customers.

Why Choose Us?

1. Professional PCB fabrication team -all engineers have years’ experience in PCB manufacturing field

2. Advanced equipments and high precision inspection & testing tools

3. Top raw materials including CCL (Copper Clad Lamination), chemistry, and solder mask ink & legend ink

4. Skilled operators with good command of all CCPs (Critical Control Points

5. Full set of surface finish equipment can do ENIG, immersion silver, immersion Tin, OSP, HASL (lead free), plating gold and plating silver without outsourcing risk.

Cutting edge printed circuit board manufacturing process capacities

6. Max aspect ratio reaches to 10 : 1

7. Max copper weight on double PCB surface can reach to 6OZ

8. The thickness of solder mask can control to 50μm

9.Min Impedance control value is 50ohm +/- 5%

10. Min NC drilling diameter 0.2mm and min laser drilling diameter is 0.1mm

11.Circuit board manufacturing strictly as per IPC standards and make sure 100% qualified

12.Strictly perform PDCA (Plan-Do-Check Action Cycle) process, and continuously improve product performance

13. Leading outstanding enterprise of energy saving and environmental protection

And demand of PCB prototype 4 layer, click here for quick quote.