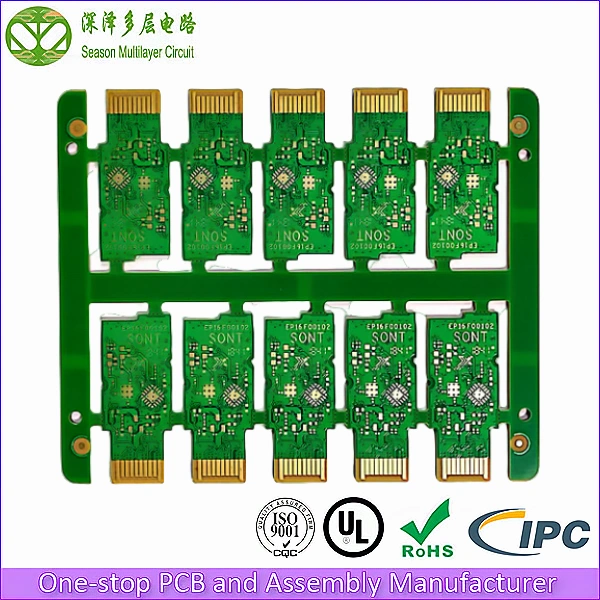

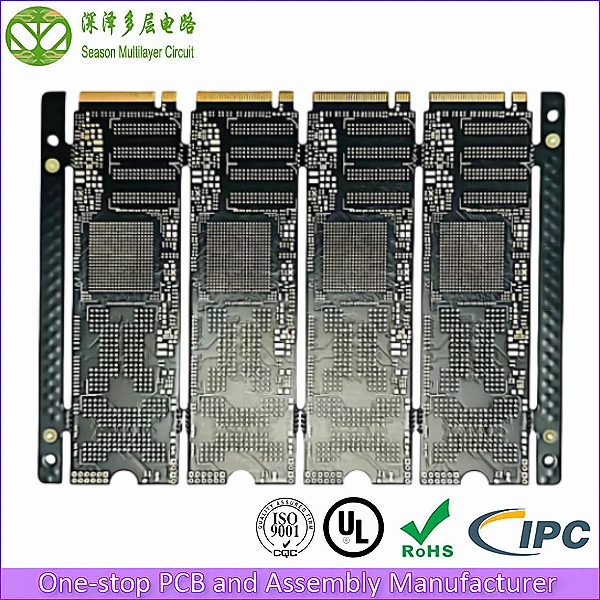

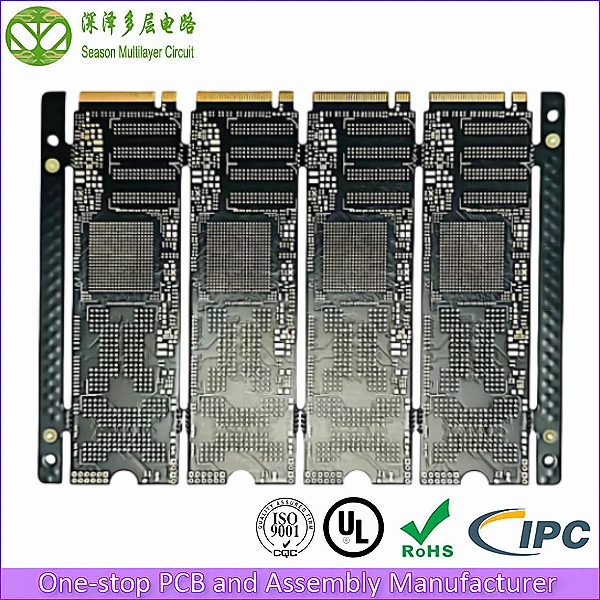

10 Layer M2 SSD PCB

M2 SSD PCB

Layer Count: 10L

Material: FR4 Tg170

Material: 0.8mm

Panel Size: 106*80mm/4

Outer Layer Copper Thickness: 1 OZ

Inner Layer Copper Thickness: H OZ

Min Via Diameter: 0.20mm

Trace Width/Spacing: 2.8/2.8mil

Min BGA Pad: 0.25mm

Surface Finish: ENIG1U’’+Hard Au5U’’

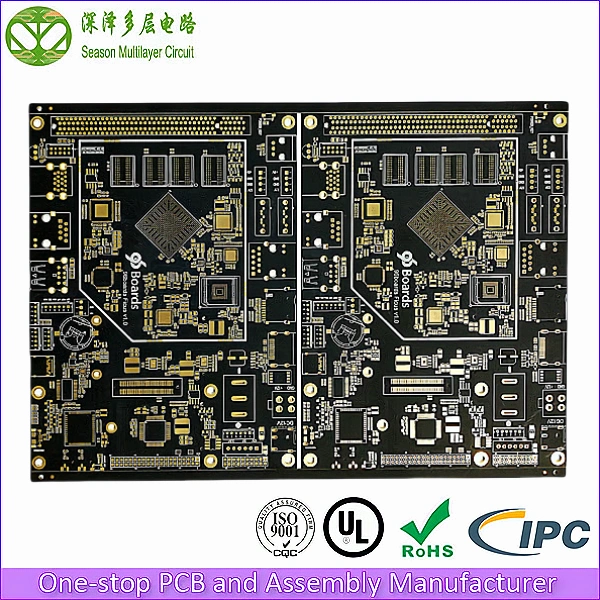

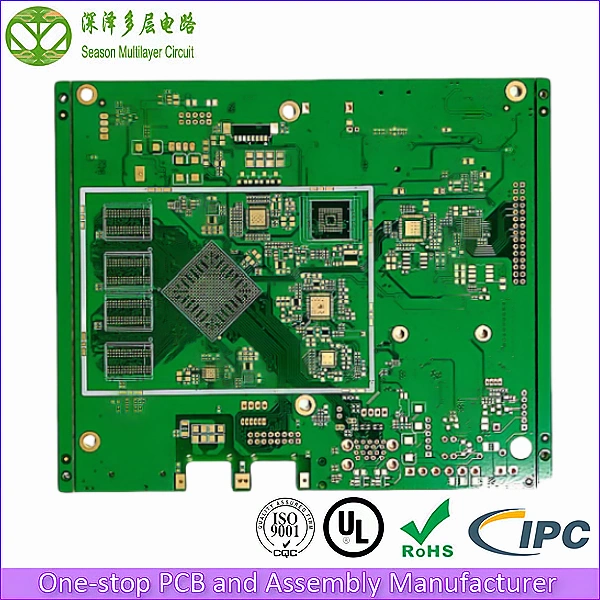

10-layer M2 SSD PCB with SMI controller for laptops, Mini PCs, Ultrabooks, and gaming consoles.

Season Multilayer Circuit pioneered 10 layer M2 SSD PCB production in 2018 when most manufacturers lacked HDI capabilities. Capitalizing on strategic equipment upgrades, Season achieved 2.8/2.8mil trace/space and 3mil ultra-thin cores through precision etching and advanced lamination processes, overcoming industry challenges to deliver high-performance storage solutions for computing devices.

SSD PCB Application Analysis and Development Trends

I. Introduction

With rapid advancements in information technology, the growing demand for enhanced computer hardware performance has elevated the importance of storage devices. As a critical interconnect component, SSD PCBs play a vital role in modern computing systems. This paper examines the applications, advantages, and future trends of SSD PCB technology.

II. Overview of SSD PCBs

SSD PCBs serve as printed circuit boards connecting host systems to solid-state drives, offering high-speed data transmission, reliability, and compact form factors. Utilizing PCIe interfaces, these PCBs achieve superior data transfer rates (up to 3.2GB/s) and reduced latency, providing robust storage support for computing architectures.

III. Applications and Advantages

- Storage Capacity

M.2 SSDs deliver exceptional storage density, with capacities like 600GB enabling extensive data storage for documents, multimedia, and gaming applications, effectively addressing space constraints in compact devices. - Data Transfer Speed

PCIe-based M.2 SSDs outperform traditional HDDs significantly. Benchmarks show PCIe 3.0 x4 interfaces achieving 3.2GB/s read and 1.8GB/s write speeds, enhancing system responsiveness and application performance by 300-400% compared to SATA SSDs. - Reliability

The absence of moving parts in M.2 SSDs ensures shock/vibration resistance, delivering 2.5× higher mean time between failures (MTBF) than mechanical drives. - Form Factor

Compact M.2 2280 dimensions (22×80mm) enable seamless integration into ultra-thin laptops and mini PCs, reducing device footprints by up to 70% compared to 2.5″ drives.

IV. Future Trends

SSD PCB technology will evolve toward:

- Higher-speed interfaces (PCIe 5.0/6.0, NVMe 2.0)

- Advanced thermal management for enterprise SSDs

- Ultra-thin designs with 0.6mm board thickness

- Embedded solutions for AI/edge computing and IoT deployments

V. Season Multilayer Circuit’s Expertise

As a leading manufacturer in HDI PCB fabrication, Season Multilayer Circuit delivers cutting-edge 10 layer M2 SSD PCBs with:

- 0.8mm ultra-thin board profiles

- 2.8/2.8 mil trace/space precision

- 3mil ultra-thin core substrates

Our advanced process capabilities in laser drilling (≥75μm microvias) and sequential lamination ensure compliance with JEDEC SSD standards. Adhering to a “Quality First” philosophy, we empower storage innovators with mission-critical PCB solutions.

VI. Conclusion

M2 SSD PCBs remain pivotal in bridging storage performance gaps across computing ecosystems. As emerging technologies like 5G and AI drive data-intensive applications, Season Multilayer Circuit will continue to pioneer next-gen PCB architectures, accelerating the evolution of storage technologies through precision engineering and customer-centric innovation.