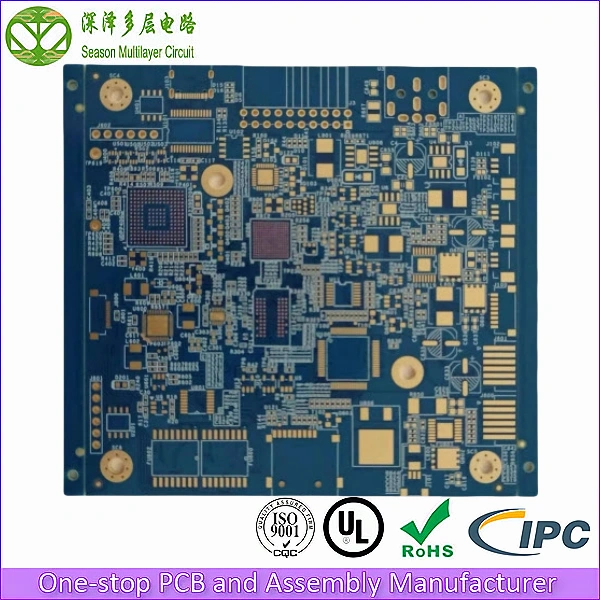

6 Layer 1st Order Rearview Mirror PCB

Rearview Mirror PCB

Layer Count: 6L(1+4+1)

Material: FR4 Tg1570

Material: 1.6mm

Panel Size: 138*162mm/2

Outer Layer Copper Thickness: 1OZ

Inner Layer Copper Thickness: 1OZ

Min Via Diameter: 0.20mm

Microvia Hole Size: 0.1mm

Trace Width/Spacing: 3/3mil

Min BGA Pad: 0.2mm

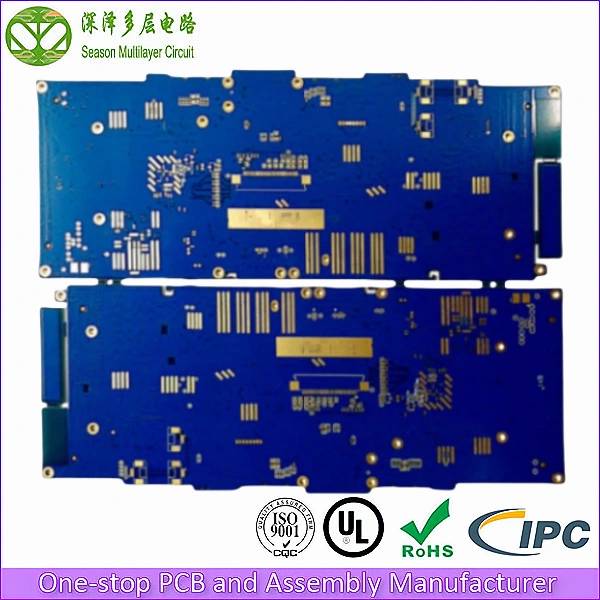

Surface Finish: ENIG1-2U’’

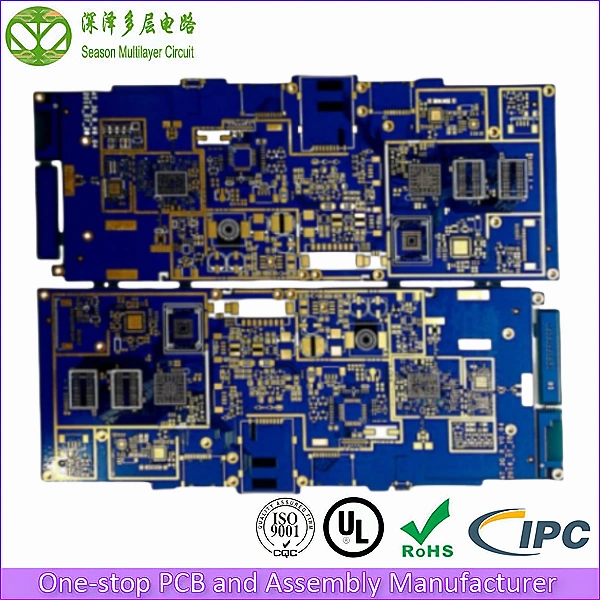

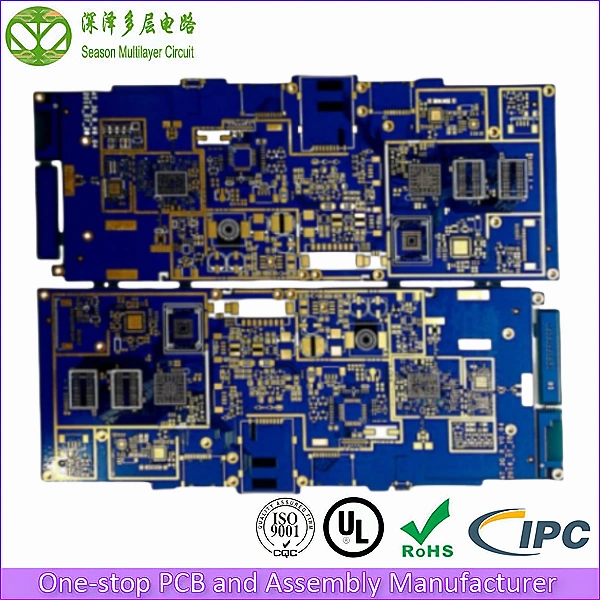

Rearview mirror pcb,utilizing Intel’s Sofia 3G-R solution, is primarily designed for automotive applications including OEM front/rear-view mirrors, aftermarket rearview mirror systems, tablet computers, and similar electronic products.

6 Layer 1st Order Rearview Mirror PCB: Elevating Driving Safety and Reliability to New Heights

In the rapidly evolving automotive industry, rearview mirrors—a critical component of driving safety—have seen continuous technological innovation. The 6 Layer 1st Order Rearview Mirror PCB (High-Density Interconnect, HDI), as an emerging technology in this field, is becoming an industry benchmark due to its exceptional performance and reliability. This article delves into the working principles, manufacturing processes, material selection, and advantages of the 6 Layer 1st Order Rearview Mirror PCB in enhancing driving safety and reliability. It also highlights the contributions and achievements of Season Multilayer Circuit in this domain.

I. Working Principles of the 6 Layer 1st Order Rearview Mirror PCB

The 6 Layer 1st Order Rearview Mirror PCB is a highly integrated electronic interconnection system that seamlessly connects complex electronic components and circuit patterns to enable diverse rearview mirror functionalities. These include heating, folding, automatic adjustment, and sensor signal transmission. Through precise control of electronic components and rapid signal processing, the PCB provides drivers with clearer and more accurate rear traffic information, significantly improving driving safety.

II. Manufacturing Process of the 6 Layer 1st Order Rearview Mirror PCB

The production of this advanced PCB involves multiple intricate steps:

- Design Phase: Engineers develop detailed schematics based on functional requirements and specifications.

- Inner-Layer Circuit Fabrication: Advanced imaging technology is used to precisely etch circuit patterns onto substrate layers.

- Layer Lamination: Multilayer substrates are bonded using high-precision lamination technology to form a compact, interconnected structure.

- Drilling and Assembly: Micro-vias are laser-drilled, followed by precise component placement and soldering to ensure electrical connectivity.

III. Material Selection for the 6 Layer 1st Order Rearview Mirror PCB

Material choices are critical to performance and durability:

- Substrate: High-performance materials like FR-4 are prioritized for their thermal stability, moisture resistance, and electrical insulation properties, ensuring reliability in harsh environments.

- Surface Coating: High-temperature-resistant solder masks and finishes (e.g., ENIG or HASL) are applied to enhance insulation, corrosion resistance, and signal integrity.

IV. Key Advantages of the 6 Layer 1st Order Rearview Mirror PCB

- High Integration: Compact design reduces space consumption while improving system reliability.

- Superior Conductivity: Advanced materials and manufacturing techniques ensure low resistance and efficient current/signal transmission.

- EMI Resistance: Optimized circuit layout and shielding materials minimize electromagnetic interference, safeguarding critical driving functions.

- Environmental Adaptability: Robust materials and coatings enable stable operation under extreme temperatures and humidity.

V. Season Multilayer Circuit’s Contributions and Achievements

Season Multilayer Circuit, a globally renowned PCB manufacturer, has established itself as a leader in automotive electronics through its expertise in 6 Layer 1st Order Rearview Mirror PCB solutions.

- Technical Excellence:

- A dedicated R&D team and state-of-the-art facilities enable customized PCB designs tailored to client specifications.

- Rigorous quality control protocols ensure compliance with automotive standards like TS16949 and IATF 16949.

- Cost-Efficiency:

- Streamlined production processes and economies of scale deliver competitive pricing without compromising quality.

- Industry Recognition:

- Season has earned accolades as a “Premium Automotive Supplier” for its innovative solutions and commitment to advancing automotive safety technologies.

Conclusion

The 6 Layer 1st Order Rearview Mirror PCB represents a transformative leap in automotive safety, combining cutting-edge HDI technology with robust engineering. Season Multilayer Circuit continues to drive industry progress through technological innovation and unwavering quality standards, empowering clients with reliable, high-performance PCB solutions. As the automotive sector evolves, such advancements will remain pivotal in shaping safer and smarter vehicles for the future.