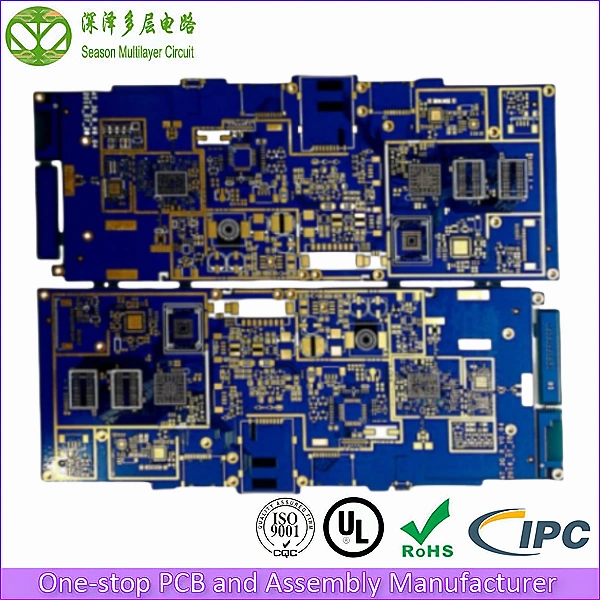

6 Layer 1st Order Automotive HUD PCB

Automotive HUD PCB

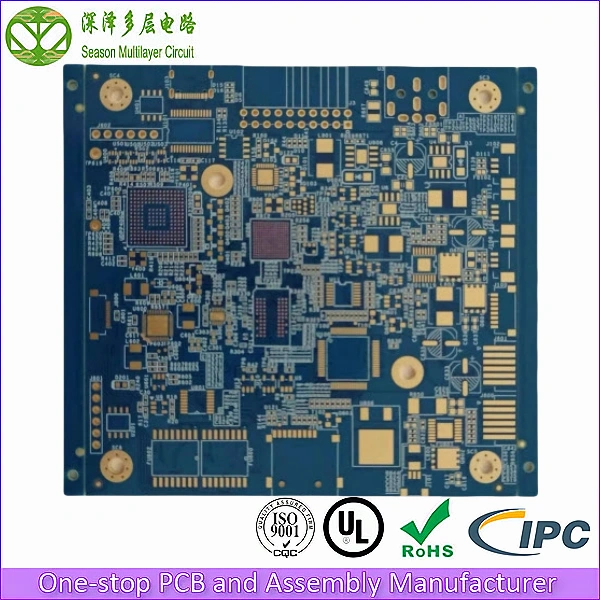

Layer Count: 6L(1+4+1)

Material: FR4 Tg170(Halogen-free)

Material: 1.6mm

Panel Size: 105*95mm/1

Outer Layer Copper Thickness: 1OZ

Inner Layer Copper Thickness: 1OZ

Min Via Diameter: 0.20mm

Microvia Hole Size: 0.1mm

Trace Width/Spacing: 3/3mil

Min BGA Pad: 0.2mm

Surface Finish: ENIG1-2U’’

6 layer 1st order automotive hud pcb,featuring halogen-free materials, is specifically designed for automotive head-up display (HUD) mainboards.

Designed for automotive head-up display (HUD) mainboards, this PCB was developed by a Shenzhen-based company specializing in optical projection technology, aiming to deliver cutting-edge driving assistance solutions.

Manufactured by Season Multilayer Circuit, the PCB completed two rigorous prototype iterations to ensure full compliance with high-performance standards. After securing automotive OEM certification, it entered mass production phase from the third batch onward, solidifying its role in advancing driving safety and convenience through precision engineering and reliable

Automotive HUD PCB: Revolutionizing Driving Safety and Convenience

With the rapid advancement of automotive technology, head-up displays (HUDs) have emerged as an innovative solution, gaining popularity among drivers. At the heart of HUD systems lies the automotive HUD PCB (printed circuit board), a critical component that shapes driving experiences by enhancing safety and convenience. This article explores the role, features, and significance of automotive HUD PCBs, along with future trends in their development.

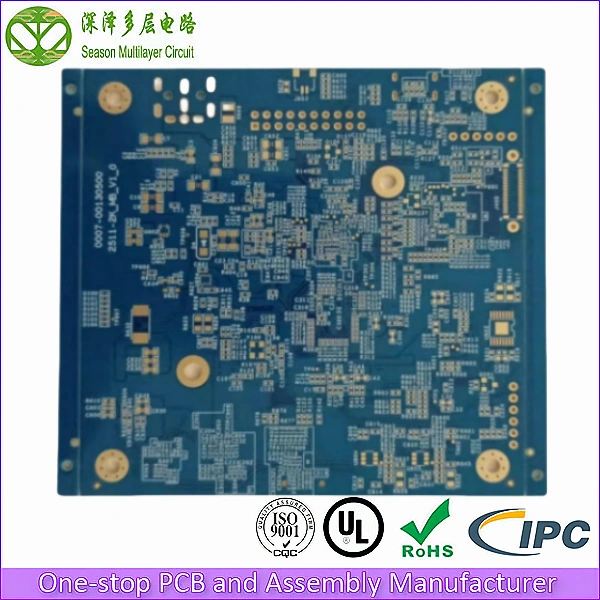

I. The Role of Automotive HUD PCBs

As the “brain” of HUD systems, automotive HUD PCBs are responsible for receiving, processing, and projecting real-time driving data, such as speed, navigation instructions, and safety alerts. By converting this information into visual signals projected within the driver’s line of sight, these PCBs eliminate the need to glance away from the road, significantly reducing distraction risks and improving situational awareness.

II. Key Features of Automotive HUD PCBs

- Compact Modular Design: Engineered for seamless integration into dashboards or windshields, these PCBs optimize space without compromising functionality.

- High-Brightness Displays & Transparent Projection: Advanced optical technologies deliver crisp, glare-free visuals that adapt to varying lighting conditions while preserving driver visibility.

- High Contrast Ratio and Wide Viewing Angles: Ensures legibility across diverse environments, from bright daylight to low-light scenarios.

III. Enhancing Driving Safety and Convenience

Automotive HUD PCBs directly contribute to safer and more intuitive driving:

- Reduced Distraction: Critical data (e.g., speed limits, lane departure warnings) is projected directly into the driver’s field of view, minimizing eye movement.

- Personalized Customization: Adjustable display layouts, brightness levels, and content prioritization cater to individual driver preferences.

- Real-Time Responsiveness: Instant processing of vehicle data ensures timely alerts for collision avoidance or route adjustments.

IV. Future Trends in Automotive HUD PCB Development

- Enhanced Precision: Integration of AI-driven sensors and algorithms for ultra-accurate vehicle state monitoring.

- Smart Interaction: Adoption of voice control, gesture recognition, and augmented reality (AR) overlays for immersive user experiences.

- 5G and IoT Integration: Seamless connectivity with onboard systems and external networks to enable real-time traffic updates, remote diagnostics, and over-the-air (OTA) updates.

- Sustainability Focus: Development of eco-friendly materials and energy-efficient designs to align with global green initiatives.

V. Conclusion

Automotive HUD PCBs are poised to become pivotal enablers of intelligent, connected vehicles. As technology evolves, these components will drive innovations in safety, customization, and interactivity, redefining how drivers engage with their vehicles.

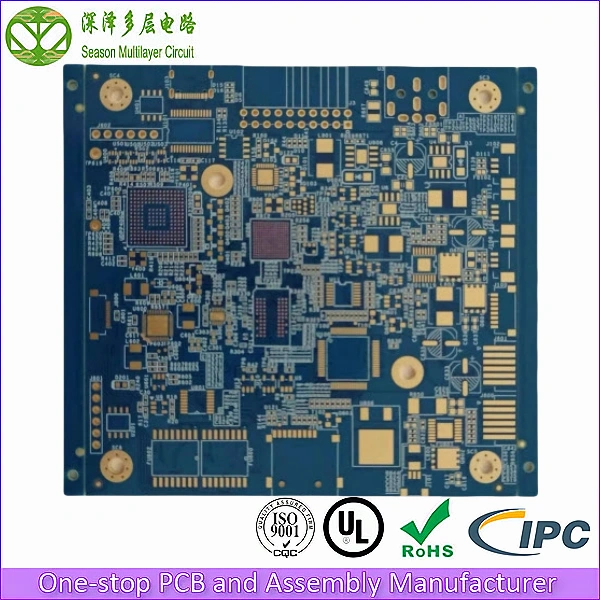

Season Multilayer Circuit: Your Partner in Advanced PCB Solutions

As a leading PCB manufacturer, Season Multilayer Circuit specializes in delivering high-performance automotive-grade PCBs, including 6 layer 1st Order HDI Automotive HUD PCBs tailored for HUD systems. Our capabilities span:

- Multilayer PCB Prototyping

- High-Frequency & High-Speed PCB Design

- SMT Assembly and PCBA Turnkey Solutions

- Customized OEM/ODM Services

Guided by our “Quality First, Customer-Centric” philosophy, we combine cutting-edge production facilities with a skilled engineering team to meet stringent automotive standards. From rigorous prototyping (two validation phases) to OEM-certified mass production, we ensure reliability at every stage.

As HUD technology advances, Season Multilayer Circuit remains committed to pushing the boundaries of PCB innovation, empowering safer, smarter, and more connected driving experiences worldwide.