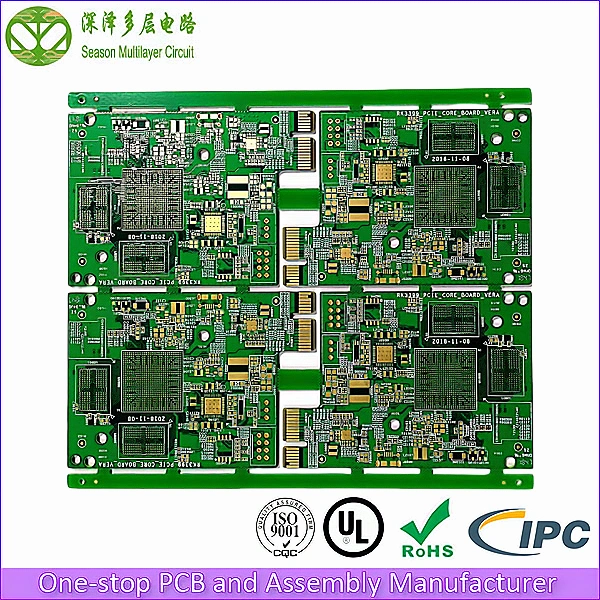

8 Layer Core PCB

Core PCB

Layer Count: 8L

Material: FR4 Tg150

Material: 1.6mm

Panel Size: 129.2*82.6mm/2

Outer Layer Copper Thickness: 1OZ

Inner Layer Copper Thickness: 1OZ

Min Via Diameter: 0.20mm

Trace Width/Spacing: 3/4mil

Min BGA Pad: 0.25mm

Surface Finish: 1-2U’’ENIG

8 layer core pcb,A compact, high-performance core component for smart devices. Features user-friendly design, simplified maintenance, and enhanced operational efficiency.

Unlocking the Potential of Rockchip RK3399 and 8 Layer Core PCB

In the era of rapid technological advancement, the performance of electronic devices hinges on cutting-edge chips and advanced PCB technologies. Today, we delve into the synergy between the Rockchip RK3399 chip and 8 layer core PCBs, exploring their pivotal roles in modern electronics.

I. Core Board PCB: Concept and Structure

The core board PCB serves as the backbone of electronic devices, integrating functional modules and enabling data transmission and processing. Unlike conventional PCBs, it features higher integration density and enhanced processing capabilities. Composed of multiple functional modules—each containing chips and related circuits—these modules interconnect via PCB connectors to form a cohesive system.

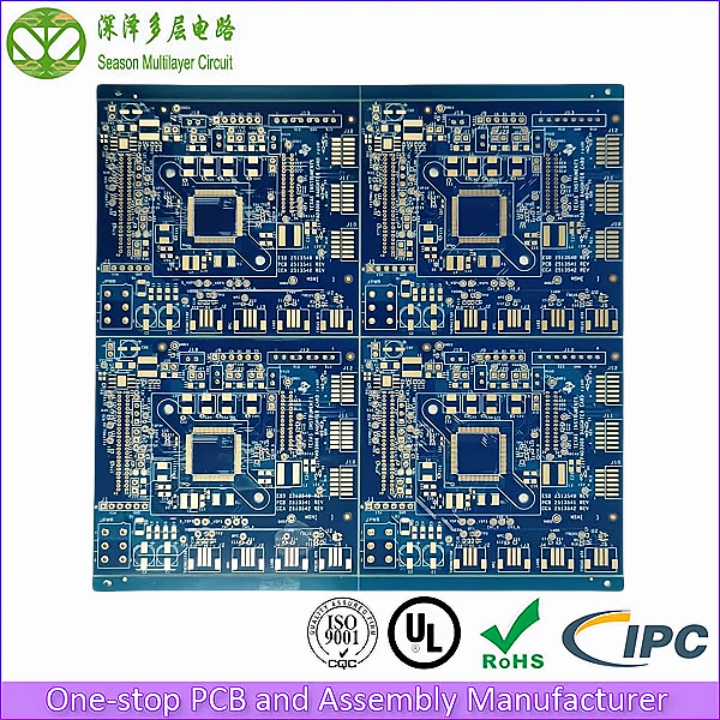

II. Advantages of 8 Layer Core PCBs

- High Integration Density:

By consolidating multiple modules into a compact design, 8-layer core board PCBs reduce device size and weight while improving reliability and stability. - Superior Processing Power:

Advanced circuit design and high-performance chips enable faster computations and data transfers, meeting modern demands for efficiency. - Scalability:

Modular expansion via connectors allows customization for diverse applications, from consumer electronics to industrial systems.

III. Rockchip RK3399 and 8-Layer Core Board PCB Integration

The Rockchip RK3399, a powerhouse chip for tablets, smart speakers, and IoT devices, pairs seamlessly with 8-layer core board PCBs. This combination delivers high performance, stability, and flexibility.

Example: In tablets, the RK3399 handles computation and graphics, while the 8-layer PCB integrates touchscreens, cameras, and storage modules—balancing portability with robust functionality.

IV. Design and Manufacturing of 8-Layer Core Board PCBs

Creating an 8 layer core PCB involves precision engineering:

- Design Phase: Optimized component selection, layout, and routing for signal integrity.

- Production Phase: High-quality materials and advanced techniques like high-density interconnect (HDI) and multilayer through-hole technology ensure performance.

Season Multilayer Circuit, a leader in PCB manufacturing, offers tailored 8-layer core board solutions for chipsets including Qualcomm, MediaTek, Rockchip, Spreadtrum, Unisoc, Allwinner, and Mstar. Their expertise spans 4- to 16-layer PCBs, incorporating HDI and multilayer via technologies for unmatched reliability.

V. Conclusion

The fusion of Rockchip RK3399 and 8 layer core PCBs drives innovation in electronics, delivering speed, stability, and versatility. Season Multilayer Circuit empowers clients with premium PCB solutions, enabling next-gen devices across industries. As technology evolves, core board PCBs will continue to redefine possibilities in connectivity and performance.