Season Multilayer technical engineering team offers full flex and rigid-flex circuit design services. During our application review and quoting process, we carefully examined specifications, materials and construction in order to minimize and eliminate any technical issues.

We also look for areas of opportunity for improving the layout and design of your flex or rigid-flex circuit's reliability and functionality. Cost reductions are also identified to generate an accurate quote that is based on a manufacturable, reliable and cost effective design by our Flexible Circuits Expert.

Radiused Corners within Flex Bend Areas

Having a radiused corner within and flex bend area reduces / eliminates stress concentrators and improves reliability.

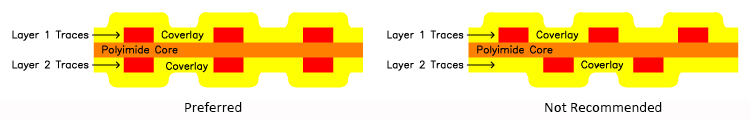

Staggered Layout to Layer Trace Positioning

Staggering your designs layer to layer trace positioning eliminates the "I-Beam" effect which improves the flexibility and reliability of your flex circuit.

|

Fillets & Teardrops

Proper fillets and teardrops eliminate stress concentrations and improves the reliability of the flexible PCB. |

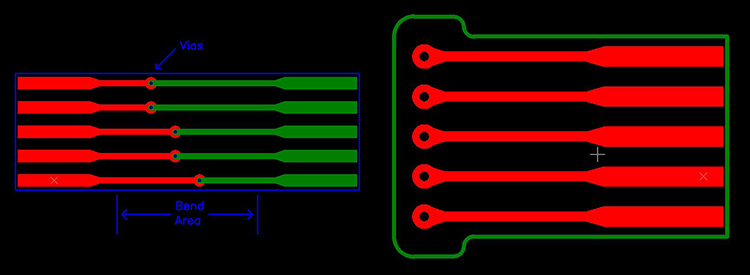

Vias within Bend Areas

This is not recommended. Having vias within a bend area can cause a significant stress concentrator which may lead to breakage. |

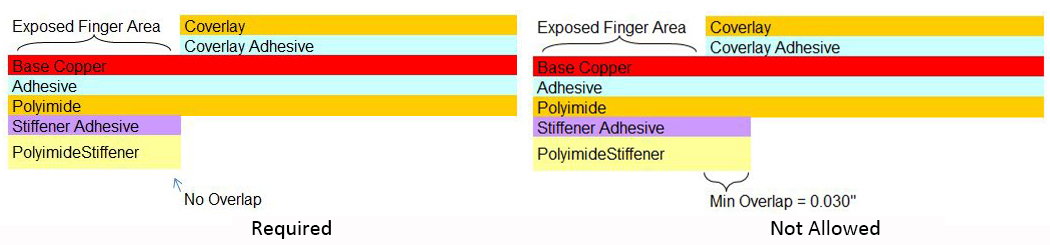

Stiffener & Coverlay Terminations

Proper stiffener and coverlay termination prevents creation of significant stress concentrator within the flexible circuit board.